Innovation-oriented and with passion in our DNA. A complete partner, offering innovative technological solutions for the coffee, beverage, pizza&bakery and professional food service sectors.

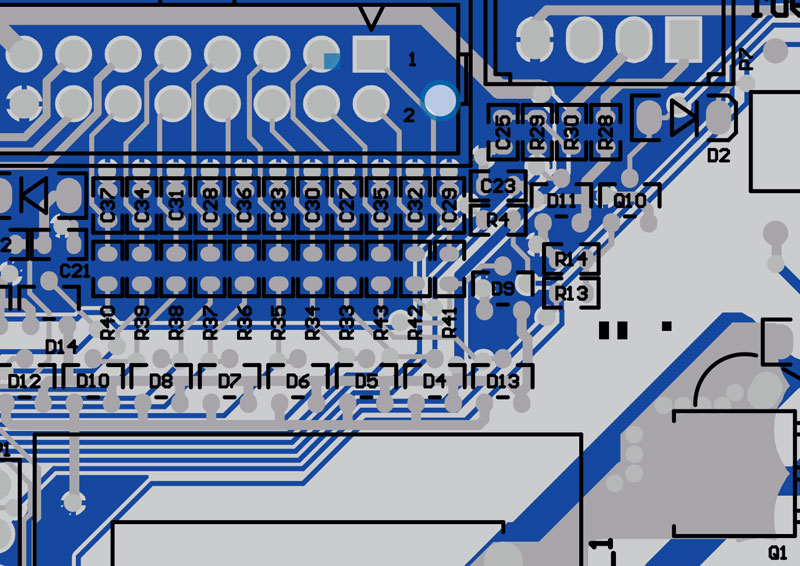

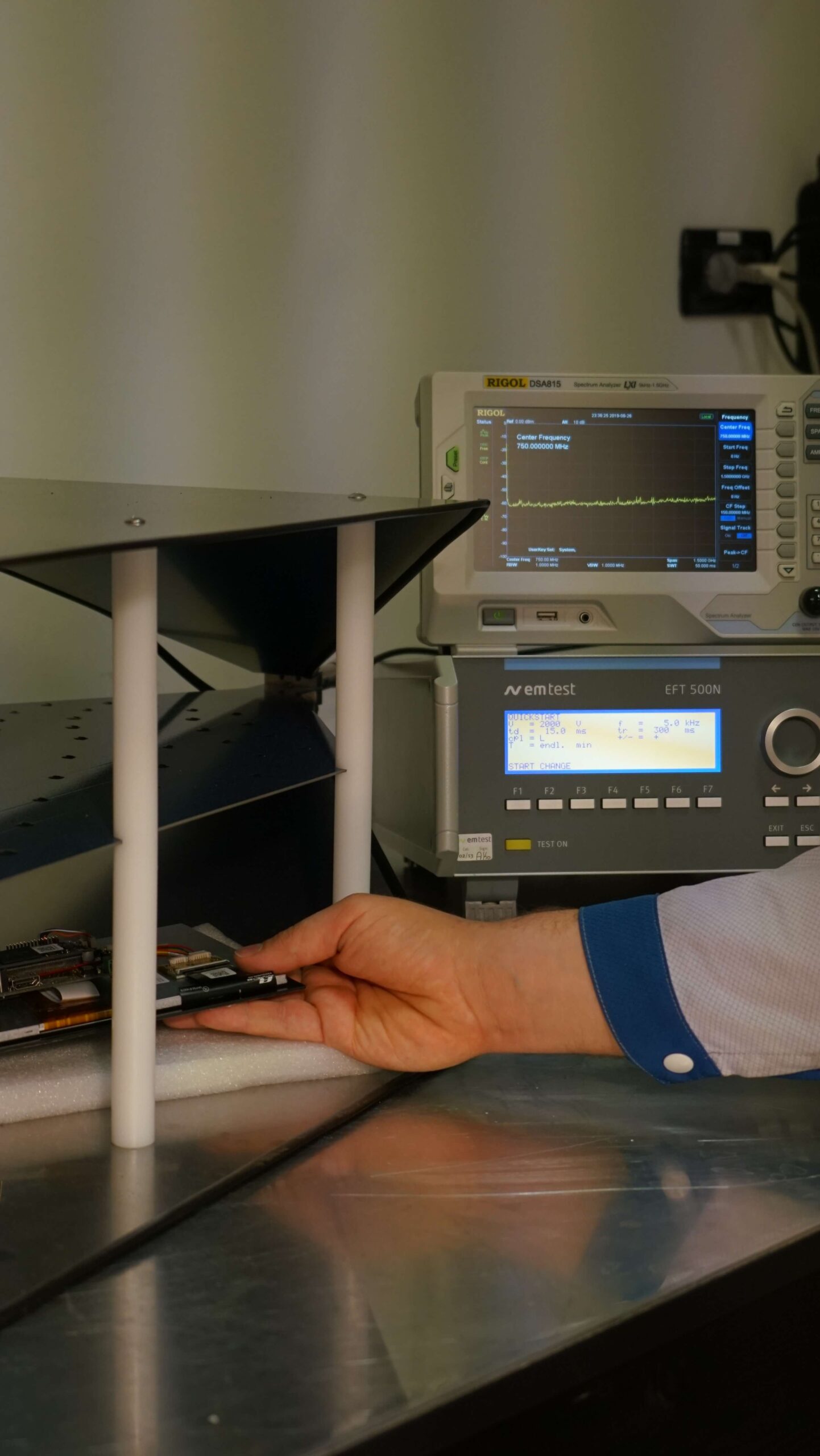

We have been working in the field of advanced electronics for professional appliances since 2009. We design and implement HMI, IoT, control electronics and wiring solutions with high specialization for these markets.

A wide range of products for realizing your most ambitious projects. Thanks to the experience we have gained over the years and our passion for this work, we have developed specific solutions for human-machine interaction, control electronics, IoT platforms for remote management of networked devices, capacitive and mechanical keyboards, level controllers, and wiring solutions for the professional appliance sectors.